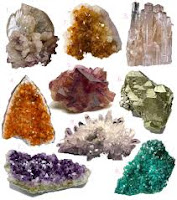

Minerals :

|

| minerals |

- The substances which are present under earth’s crust having compound of metals are called minerals.

- Some minerals contain high percentage of metals where as some contain low percentage.

Ores:

- Those minerals from which extraction of metals are done easily as well as profitably are called ores.

- An ore contains high percentage of metal .

- All the ores are minerals but all the ores are not minerals.

minerals example: Some metals and their ores

Metal | Ore | Formula |

Sodium | Rock salt | NaCl |

Aluminium | Bauxite | Al2O3 . 2H2O |

Manganese | Pyrolusite | MnO2 |

Iron | Haematite | Fe2O3 |

Mercury | Cinnabar | Hgs |

Zinc | Calamine Zinc blende | ZnCO3 ZnS |

Copper | Cuprite Copper glance | Cu2O Cu2S |

How are minerals formed

Extraction of metals:

- The process of obtaining metal from its ore is called extraction of metal.

- The extraction of metal is done by some process which depend on three factors. Type of ores, nature of impurity and reactivity of metal.

Extraction of Highly Reactive Metals:

- The highly reactive metals (K,Na,Ca,Mg ) are extracted from their molten chloride by the electrolyte reduction . This process is called electrolysis. .

- Separation of cations and anions from salt by electricity is called electrolysis.

- In electrolysis , negatively charged electrode ( also called cathode ) reduce metal cations into neutral metal. Thus metal deposit at cathode.

- Chlorine gas evolved at positive electrode ( Anode ).

For example:

- Extraction of sodium metal from molten NaCl:

- When electric current is passed through molten sodium chloride, then sodium is formed at cathode. At anode chlorine gas is evolved.

2NaCl → 2Na + Cl2 ( Electrolysis )

Mechanism:

- Molten sodium chloride consist cations (Na+) and anions ( Cl- ).

- During electrolysis of molten sodium chloride , cations (Na+) move toward cathode and anions ( Cl- ) moves toward Anode plate due to attraction.

- At cathode ,cations (Na+) take electrons from negative electrode to reduce into sodium metal. So sodium metal is formed at cathode.

- At anode, anions ( Cl- ) provide electron to positive electrode to oxidize into chlorine gas .

NaCl → Na+ + Cl- ( Molten state )

Na+ + e- → Na ( At cathode )

Cl- → e- + Cl ( At anode )

Cl + Cl → Cl2

- Aqueous solution of sodium chloride is not used in place of molten NaCl because of sodium formed at cathode react rapidly with water to form sodium hydroxide. And hence sodium metal is not formed at cathode.

- So electrolysis of aqueous solution of NaCl gives sodium hydroxide .

Extraction of Aluminium metal:

- Alumiium metal is extracted from its molten oxide by the electrolyte reduction .

- In electrolysis, cathode reduces cations ( Al+3 ) into Aluminium metal . Thus Aluminium metal is deposited at cathode.

- oxygen gas is evolved at positive electrode ( Anode ).

2Al2O3 → 4 Al + 3 O2 ( Electrolysis )

Mechanism:

- Molten aluminium oxide consist cations (Al3+) and anions ( O2- ).

- During electrolysis of molten aluminium oxide cations (Al3+) move toward cathode and anions ( O2- ) moves toward Anode plate due to attraction.

- At cathode , cations (Al3+) take electrons from negative electrode to reduce into aluminium metal. So Aluminium metal is formed at cathode.

- At anode, anions ( O2- ) provide electrons to positive electrode to oxidize into Oxygen gas .

Al2O3→ 2Al3+ + 3 O2- ( Molten state )

Al3+ + 3 e- → Al ( At cathode )

O2- → 2e- + O ( At anode )

O + O → O2

Reduction of Metal Oxide:

- Oxide of moderately or less reactive metals can be reduced by carbon (Coke) , aluminium or sodium to form metals.

Reduction By Carbon:

- In this method, Coke is mixed with metal oxide and heated in a furnace. Carbon reduces metal oxide to form metal.

e.g ZnO (s) + C (s) → Zn (s) + CO (g)

- Metals which are less reactive than Zinc ( e.g Iron, tin, lead , copper ) are also extracted by this method.

Reduction of Metal Oxide by Aluminium powder :

- Aluminium powder can be used to extract those metals which are less reactive than aluminium. Thus reaction are displacement reaction.

- Aluminium powder is used in those case where oxide of metals like Manganese and chromium are are not satisfactory reduced by carbon.

For example:

- When manganese dioxide is heated with aluminium powder as reducing agent, then manganese metal is produced.

3MnO2 (s) + 4 Al → 3Mn(l) + 2Al2O3 (s) + Heat

- This reaction is highly exothermic. So Manganese is formed in molten state.

Thermite Reaction:

- The reduction of metal oxide by using aluminium powder is called thermite reaction.

- In this reaction large amount of heat is evolved. Thus reduced metal is obtained in molten state.

- Thermite reaction is used in thermite welding for joining the two pieces of irons.

Fe2O3 (s) + 2 Al (s) → 2Fe (l) + Al2O3 (s) + Heat

- A mixture of iron (III ) oxide and aluminium powder is ignited with a burning magnesium ribbon.

- Aluminium reduces iron oxide to produce molten iron metal due to heat .

- The molten iron is then poured between the broken iron pieces to weld them .

Calcination:

- The process in which a metal carbonate ore is strongly heated in the absence of air to produce metal oxide is called calcinations.

- e.g. when calamine ore is heated strongly ,then zinc oxide is formed.

ZnCO3 (s) → ZnO (s) + CO2 (g)

- After calcination, zinc oxide is reduced by coke into zinc metal.

ZnO (s) + C (s) → Zn (s) + CO (g)

Roasting:

- The process in which a metal sulphide ore is strongly heated in presence of air to produce metal oxide is called Roasting.

- e.g. when zinc blend ore is heated strongly ,then zinc oxide is formed.

2ZnS (s) + 3 O2 → 2ZnO (s) + 2SO2 (g)

- After roasting, zinc oxide is reduced by coke into zinc metal.

ZnO (s) + C (s) → Zn (s) + CO (g)

Extraction of Very Less Reactive Metals :

- Less reactive metals are present in earth’s crust as compound of sulphide. So , sulphide ore is converted into metal oxide by roasting process .

- When oxide of less reactive metal is strongly heated then it get reduced to form metal.

Extraction of Mercury:

- Mercury metal can be extracted by cinnabar ore ( HgS ) in two step[s.

- Step 1. Concentrated Cinnabar is roasted in air to form mercury oxide.

2HgS (s) + 3 O2 → 2HgO (s) + 2SO2 (g)

- Step 2 : Mercury oxide ( HgO) is strongly heated at 300 o C to form mercury metal.

2HgO (s) → 2 Hg (l) + O2 : on heating

Extraction of Copper:

- Copper metal is extracted by copper glance ( Cu2S ) ore in two steps:

- Step 1: The concentrated copper glance is roasted in air to form copper oxide.

2Cu2S (s) + 3 O2 → 2 Cu2O (s) + 2SO2 (g)

- Step 2 : When good amount of cooper sulphide has been converted into copper oxide , then the supply of air for roasting is stopped.

- In the absence of air , copper oxide react with remaining copper sulphide to form copper metal.

Cu2S (s) + 2 Cu2O (s) → Cu (s)+ 2SO2 (g)

Refining of metals:

- The metal obtained from various reduction process are not pure. It consist some impurity.

- The process of purifying impure metal is called refining of metal.

- Refining of metal is generally done by electrolysis process . it is called electrolytic refining.

- Less reactive metals like zinc, copper, tin , lead , silver, gold, chromium and nickel are refined by electrolysis process .

Electrolytic refining:

- The essential components used in electrolytic refining are Anode, cathode, electrolyte, and battery.

Anode:

- A thick block of the impure metal is used as anode plate. It is connected to positive terminal of battery. Oxidation is occurred at anode. From anode Soluble impurity go into solution whereas insoluble impurity get deposited at bottom of anode as anode mud.

Cathode:

- A thin strip of the pure metal is used as cathode plate. It is connected to negative terminal of battery. Reduction is occurred at cathode. Pure metal is gets deposited at cathode.

Electrolyte:

- A water soluble salt of metal which has to be refined is used as electrolyte. Electrolyte is acidified by dilute sulphuric acid for proper conduction of electricity.

No comments:

Post a Comment